Correct selection of industrial hose products for high temperature applications is very important for safe and efficient operation. The following are key factors of high adaptability industrial hose , including material characteristics, structural design and application requirements, to ensure the best performance in extreme high temperature conditions.

The material composition of an

industrial hose

determines its resistance to high temperatures and must be carefully evaluated based on the specific thermal range of the application. Common materials include synthetic rubber compounds such as EPDM (ethylene propylene diene monomer) and silicone, which offer excellent heat resistance while maintaining flexibility. EPDM is particularly suitable for

Thermoplastic materials like PTFE are often used in hot oil hose constructions because they combine exceptional thermal stability with chemical resistance. These hoses can operate continuously at temperatures up to 450°F while resisting degradation from petroleum-based fluids. The inner liners of such hoses are frequently reinforced with multiple layers of high-tensile textile or metal braids to prevent collapse under vacuum conditions, particularly important for oil suction hose applications in high-temperature environments.

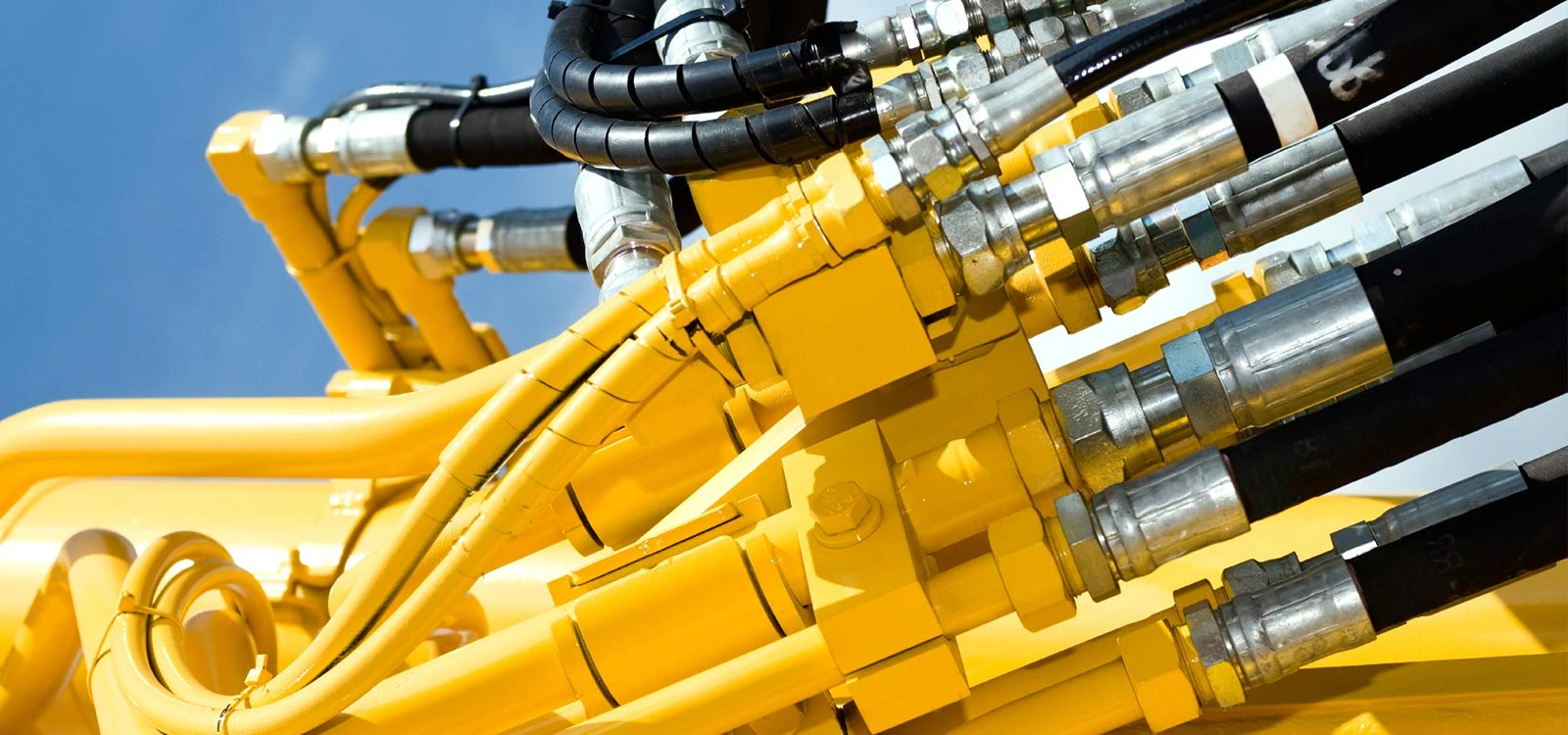

Reinforcement layers significantly enhance the performance of high-temperature hoses. A braided oil pressure line typically incorporates multiple layers of high-grade stainless steel wire braiding between the inner tube and outer cover. This construction not only provides superior burst pressure ratings but also minimizes expansion under high temperatures, ensuring consistent flow characteristics. Similarly, flexible steam pipe designs often feature spiral-wound stainless steel reinforcement that maintains hose shape and prevents kinking while allowing for necessary movement in steam transfer systems.

The structural design of an

industrial hose

must account for both thermal and mechanical stresses encountered in high-temperature applications. Single-braid constructions are commonly used for

Double-braided designs provide enhanced performance for extreme conditions. In oil suction hose applications involving high-viscosity fluids at elevated temperatures, the dual reinforcement layers prevent hose collapse while maintaining fluid transfer efficiency. The inner braid typically consists of high-tensile synthetic fibers for flexibility, while the outer braid uses corrosion-resistant steel wires for structural support. This combination ensures the hose maintains its shape and flow characteristics even when handling heated oils or other viscous media.

Thermal expansion management is a critical aspect of hose design for high-temperature service. Flexible steam hose products often incorporate special construction techniques to accommodate dimensional changes. Some designs feature corrugated metal cores that allow for expansion and contraction without compromising the steam barrier, while others use specially formulated elastomers that maintain their physical properties across wide temperature ranges. The connection points, where thermal stress is most concentrated, frequently employ forged steel fittings with precision machining to ensure leak-proof seals even after repeated thermal cycling.

Different industries require tailored

industrial hose

solutions based on their thermal and operational demands. In food processing, hoses must endure both high-temperature sanitation (up to 180°F/82°C) and hot oil transfer, necessitating FDA-approved

Steam applications present unique challenges where braided steam hose or flexible steam pipe options are selected based on temperature and pressure ranges. Plant steam service typically uses EPDM-lined hoses for 150 psi at 366°F/186°C, while superheated steam systems require PTFE-lined versions rated for 750°F/400°C. Pneumatic systems in heated environments need specialized industrial air hose designs that resist hardening from continuous hot air exposure while maintaining flexibility.

Each application requires careful assessment of temperature extremes, pressure fluctuations, chemical exposure, and mechanical stresses to ensure optimal hose performance and longevity. Manufacturers provide detailed specifications to match hose capabilities with specific operational parameters, preventing premature failures in critical systems.

After a comprehensive evaluation of the material, structure and operating conditions of the industrial table, it is a wise choice to choose industrial hose from Sinopulse under high temperature conditions. This choice and subsequent operation can ensure reliable tower performance while minimizing safety risks and time in a strictly demanding environment.