An industrial hose is a flexible tube designed for transferring various fluids, gases, or materials in industrial applications. These hoses are made from different materials, such as rubber, PVC, thermoplastics, or metal, and are often reinforced with braided, spiral, or textile layers to withstand high pressures, extreme temperatures, or abrasive materials. Industrial hoses serve diverse purposes, from transferring water, chemicals, and fuel to handling food products, sandblasting, and steam cleaning. They are commonly used in industries like manufacturing, construction, oil and gas, mining, agriculture, and food processing.

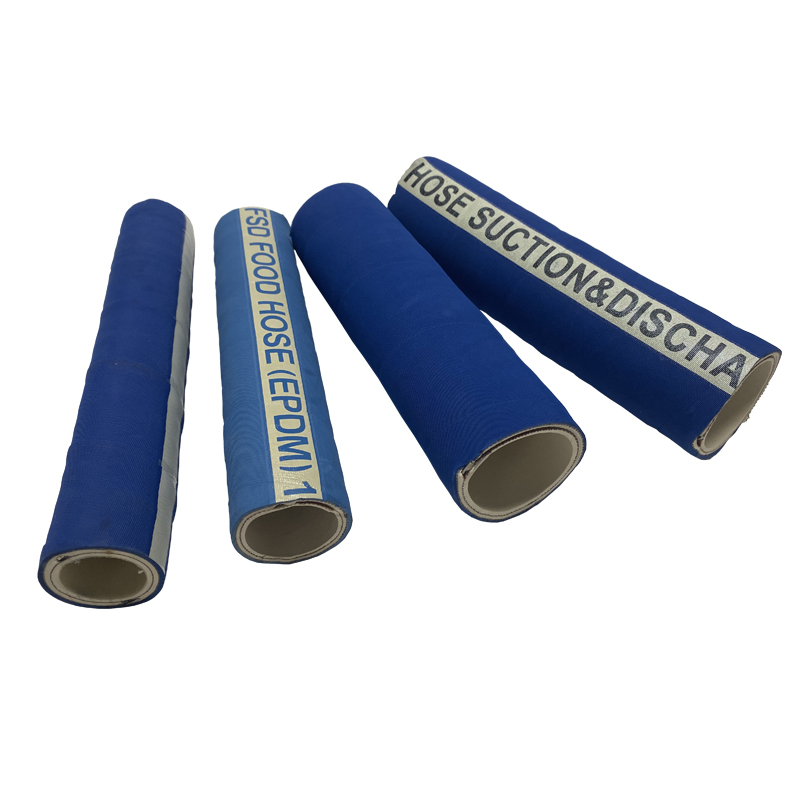

For example, in the construction sector, industrial hoses transport water and cement mixtures or operate pneumatic tools. In agriculture, they irrigate fields and distribute fertilizers. Chemical plants use specialized hoses resistant to corrosive substances, while food-grade hoses in the food industry ensure sanitary handling of consumable products. The versatility and reliability of industrial hoses make them an integral part of operations that require efficient and safe material transfer under demanding conditions.

Industrial hoses, while durable, are not immune to failure. Over time, they can develop cracks, bulges, leaks, bursts, or twisting deformities due to operational stress, environmental exposure, or improper maintenance. One common factor behind premature failure is improper installation. If a hose is bent beyond its minimum bend radius or twisted during assembly, it experiences excessive internal stress, which leads to fatigue and cracking.

Temperature extremes are another major cause. Excessive heat can degrade rubber compounds, while freezing conditions can cause hardening and micro-cracking. Similarly, chemical incompatibility with the conveyed fluid can erode the inner lining, resulting in leaks or swelling. Continuous vibration or movement can also cause chafing, which wears through the hose cover and eventually exposes the reinforcement layer. Once the reinforcement is compromised, the hose loses its ability to handle pressure and may burst suddenly.

Choosing the correct automotive hose sizes or industrial hose dimensions is crucial for preventing premature failure. Undersized hoses restrict flow, leading to pressure spikes and heat buildup, while oversized hoses can cause turbulence and reduced efficiency. Both cases place unnecessary stress on the hose and fittings.

When selecting hose sizes, engineers must consider flow rate, pressure, and compatibility with the system’s fittings. Manufacturers provide detailed size charts and dimensional data to ensure accurate selection. In automotive and industrial systems, hose diameter directly affects performance and lifespan. A properly sized hose reduces vibration, enhances pressure stability, and prevents over-flexing, which are key to avoiding cracks or leaks during long-term operation.

Another vital aspect is the working pressure (WP) and burst pressure (BP) rating. The working pressure represents the maximum continuous pressure the hose can handle safely, while the burst pressure is typically four times higher. Maintaining a safety margin between system pressure and WP ensures the hose operates within its safe range. Ignoring this can lead to deformation, blistering, or catastrophic rupture.

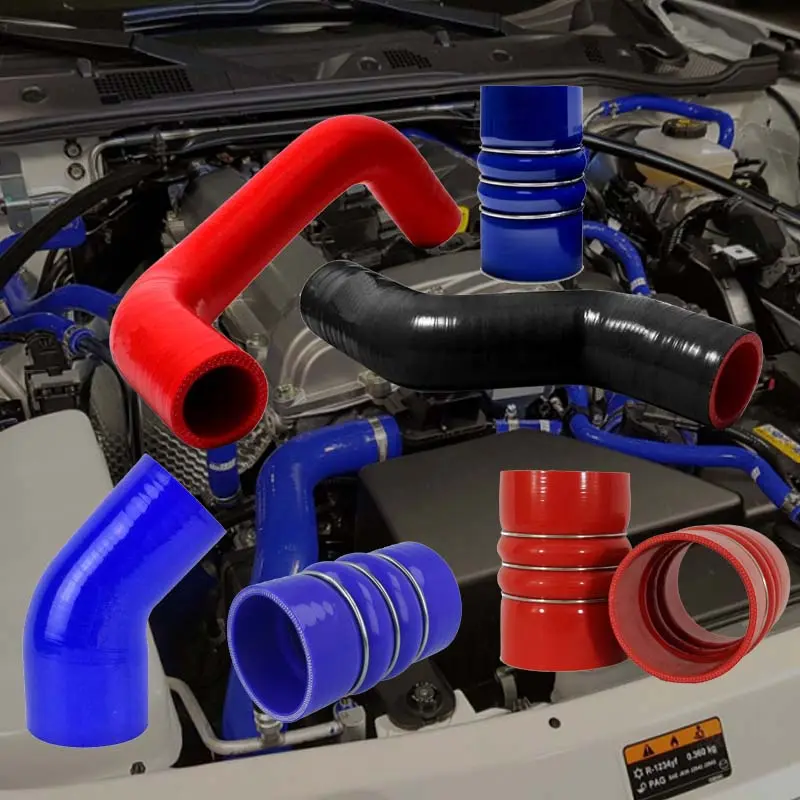

When dealing with specialized systems, custom automotive hoses are often the best solution. These hoses can be tailored to specific chemical compatibility, temperature ranges, and mechanical requirements. For instance, hoses made of EPDM rubber perform well in hot water or steam environments, while nitrile rubber is ideal for oil and fuel transfer. Thermoplastic hoses, on the other hand, resist corrosion and are lightweight, making them suitable for pneumatic and hydraulic systems.

Customization also extends to reinforcement types—whether braided steel, textile, or spiral layers—depending on the pressure and flexibility needed. In automotive and industrial settings, custom hoses help reduce downtime and ensure compatibility with unique machinery layouts. By choosing custom hoses that meet the specific operating conditions, users can minimize failures due to material mismatch or insufficient reinforcement.

Improper material choice, however, remains one of the most common causes of hose degradation. For instance, using a hose not resistant to certain chemicals can result in softening, swelling, or blistering of the inner layer. Regular review of material data and application compatibility helps prevent such issues.

The environment where an industrial hose operates significantly influences its service life. Prolonged exposure to sunlight, ozone, moisture, or chemicals can weaken the outer cover, leading to cracking and reduced flexibility. High ambient temperatures accelerate material aging, while abrasive surroundings—such as concrete dust or sharp metal edges—can wear down the cover and compromise the reinforcement layer.

Pressure surges and pulsations are also major contributors to failure. Repeated expansion and contraction cause fatigue over time, particularly near fittings where stress is concentrated. For hoses used in high-pressure applications, selecting appropriate reinforcement and end fittings is essential. This is where an experienced

Maintenance practices such as regular inspection and timely replacement can further prevent failures. Look for early warning signs such as bulges, leaks, or discoloration. Hoses showing surface cracks or stiffness should be replaced immediately to prevent sudden rupture. Proper storage—away from heat and UV exposure—can also extend the lifespan of industrial hoses.

There are numerous types of industrial hoses available, each designed for specific operational conditions. Water hoses are used in irrigation and cleaning; air hoses connect pneumatic tools; fuel and oil hoses handle petroleum-based fluids; chemical hoses are made with corrosion-resistant linings; and food-grade hoses ensure hygiene during beverage or dairy transfer.

Understanding the application is crucial for choosing the right type. For instance, a steam hose must withstand high temperatures and pressure, while a sandblast hose must resist abrasion from grit particles. Selecting an inappropriate type can lead to rapid deterioration, leaks, or blowouts. Consulting with manufacturers and referencing product data sheets helps in identifying the most suitable hose construction, diameter, and reinforcement design for your needs.

It’s also important to ensure that fittings and couplings match the hose material and size. Misalignment or incompatible fittings are common causes of leakage and detachment under pressure. Using genuine manufacturer-recommended components minimizes these risks.

Industrial hose failure is rarely caused by a single factor. Instead, it’s usually the result of multiple issues, including improper installation, incorrect sizing, incompatible materials, and environmental stress. By understanding these causes and implementing preventive maintenance practices, industries can greatly extend the lifespan of their hoses and reduce downtime.

Working closely with an experienced industrial hose manufacturer ensures that the correct materials, sizes, and fittings are used for each specific application. Regular inspection, testing, and replacement schedules further guarantee reliable performance. In complex systems like automotive manufacturing or heavy machinery, combining proper design, material selection, and installation procedures is key to preventing leaks, bursts, and costly production halts.

Cracking, bulging, leakage, and bursting often result from excessive pressure, chemical incompatibility, or improper installation.

Perform regular inspections, ensure proper hose routing, and replace damaged hoses before they fail. Always use the correct size and material for your application.

Yes, custom automotive hoses can be designed to meet specific industrial requirements, provided they are made from compatible materials and tested for relevant pressures.

Refer to automotive hose sizes or industrial sizing charts provided by the manufacturer to ensure proper flow rate, pressure capacity, and fit.

A qualified industrial hose manufacturer offers expertise, quality control, and customization options that ensure the hose meets international safety and performance standards.

Product Application