- Description

- Product Tags

-

Key Features:

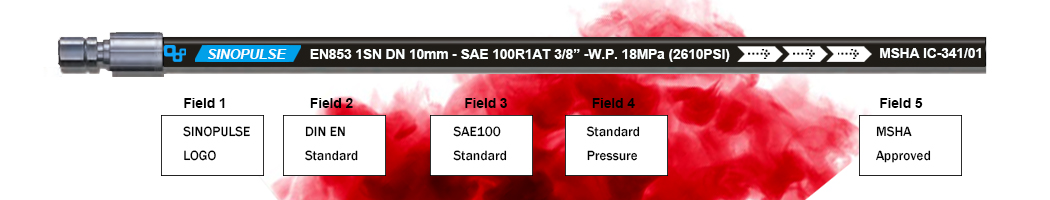

EN/DIN and New SAE rated working pressure

Hydraulic hose R5

Flame resistant property of the cover compoud, MSHA approved

FRAS, MSHA, ISO approved

OEM brand hose layline

Part No.

I.D.

O.D.

W.P

B.P

B.R

W.T

Dash

Inch

mm

mm

MPa

PSI

MPa

PSI

mm

kg/m

R5-03

3/16″

4.8

13.0

20.7

3000

82.8

12000

75

0.228

R5-04

1/4″

6.4

14.6

20.7

3000

82.8

12000

85

0.258

R5-05

5/16″

7.9

17.0

15.5

2250

62

9000

100

0.327

R5-06

13/32″

9.5

19.3

14.0

2000

56

8000

115

0.385

R5-08

1/2″

12.7

23.2

12.1

1760

48.4

7040

140

0.543

R5-10

5/8″

15.9

27.2

10.3

1500

41.2

6000

165

0.659

R5-14

7/8″

22.2

31.4

5.5

800

22

3200

185

0.704

R5-18

1-1/8″

28.6

38.1

4.3

630

17.2

2520

230

0.945

R5-22

1-3/8″

34.9

44.5

3.5

508

14

2000

265

1.077

R5-29

1-13/16″

46.0

56.4

2.4

350

9.6

1400

335

1.593

R5-38

2-3/8″

60.3

73.0

2.4

350

9.6

1400

610

2.583

R5-48

3″

76.2

90.5

1.4

200

5.6

800

840

3.462

Application:Suitable for oil or water based hydraulic fluids.

It is suitable for impacted medium pressure hydraulic petroleum-based oils, lubricating oils, overheating lubricating oil and water & air piping, such as air brake, power steering, fuel filter, turbocharger and oil cylinder of heavy commercial vehicles.

Our Company:

Sinopulse is a market-leading manufacturer of hydraulic hoses and fittings with about 20 years experience.

Our hydraulic hoses can deliver high presure oil and stand the hardest working environment.

Each of our hydraulic hose is in compliance with stringent industry standards such as DIN EN and SAE 100.

Our steel wire reinforced rubber hose can fit in a range of adapters and fittings.

Hydraulic hose is designed to be used with petroleum and water based hydraulic fluids. It can handle gasoline, diesel fuels, mineral oils, glycol, lubricating oils, etc.

Hydraulic hose works in high pressure environment applications, from agriculture, manufacturing to all kinds of heavy equipment operations.

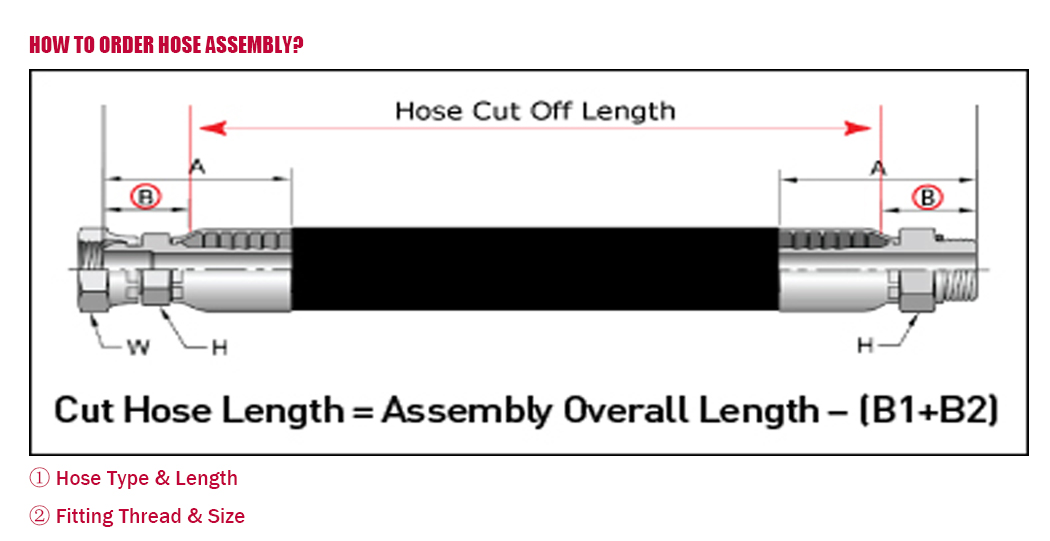

We can also make hydraulic assembly for customers. The finished assemblies are hydraulic hoses with crimped fittings pre-attached. We customize the type of hose, length,and fittings to create the perfect assemblies for you.

We have a large hydraulic hose range, which can satisfy your different applications.

SAE100 R1AT/EN 853 1SN (ONE STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R2AT/EN853 2SN (TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

DIN 20023/EN 856 4SP (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

DIN 20023/EN 856 4SH (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R12 (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R13 (FOUR OR SIX STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R15 (SIX STEEL WIRE SPIRAL HYDRAULIC HOSE)

EN 857 1SC (ONE STEEL WIRE BRAIDED HYDRAULIC HOSE)

EN857 2SC (TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R16 (ONE OR TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R17 (ONE OR TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R3 / EN 854 2TE (TWO FIBRE BRAIDED HYDRAULIC HOSE)

SAE100 R6 / EN 854 1TE (ONE FIBRE BRAIDED HYDRAULIC HOSE)

SAE100 R5 (FIBER BRAIDED COVER HYDRAULIC HOSE)

SAE100 R4 (HYDRAULIC OIL SUCTION HOSE)

SAE100 R14 (PTFE SS304 BRAIDED)

SAE100 R7 (ONE WIRE OR FIBRE BRAIDED THERMOPLASTIC HOSE)

SAE100 R8 (TWO WIRE OR FIBRE BRAIDED THERMOPLASTIC HOSE)

Core Structure Analysis of SAE 100 R5 Steel Wire-Reinforced, Textile Covered Hydraulic Hoses

Core Structure Analysis of SAE 100 R5 Steel Wire-Reinforced, Textile Covered Hydraulic HosesAs a trusted hydraulic hose manufacturer, SINOPULSE engineers SAE 100 R5 hoses with a meticulously designed structure, ensuring reliable low-pressure fluid transfer across diverse industrial applications. These fabric-reinforced hydraulic hoses stand out for their optimal balance of durability, flexibility, and chemical resistance, making them the go-to choice for suction and return lines in construction, agriculture, and manufacturing sectors.

At the heart of SINOPULSE 100 R5 hoses lies the inner tube, crafted from premium oil-resistant synthetic rubber. Engineered to meet the stringent requirements of mineral-based hydraulic fluids, this layer not only ensures seamless compatibility but also effectively prevents swelling or degradation over time. The smooth inner surface of the tube plays a crucial role in reducing friction, thereby minimising pressure loss during fluid suction and ensuring efficient operation of hydraulic systems.

The reinforcement layer is the cornerstone of R5 hoses’ performance. Comprising one layer of high-strength steel wire braiding, typically made from polyester or nylon, this fabric reinforcement provides exceptional flexibility without compromising structural integrity. Capable of withstanding low and medium pressures of up to 20bar-210 bar.

Protecting the hose’s inner components is the outer cover, constructed from a braided textile sheath. The outer cover makes it more wear-resistant. SAE 100R5 hose is widely used in hydraulic and lubrication systems of trucks, industrial equipment and military machinery. It is suitable for conveying media such as oil, air and fuel. It has good temperature resistance and wear resistance and is suitable for medium and low pressure application scenarios.

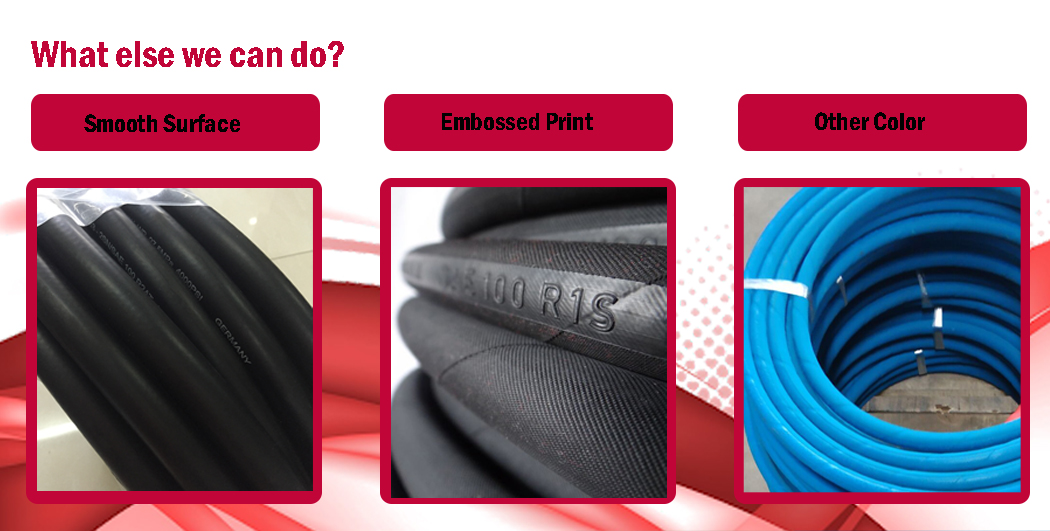

Understanding that one size does not fit all, SINOPULSE offers comprehensive customization options for R5 hoses. From tailored lengths to a wide range of end fittings and specific marking requirements, our team of experts works closely with clients to develop custom braided hose solutions that precisely match the unique needs of their hydraulic systems. Whether you require a standard 100 R5 hose for routine applications or a specialised custom variant for complex setups, SINOPULSE’s engineering expertise ensures superior performance and reliability.

What is the Pressure Rating of R5 Hose?

The pressure rating of SAE 100 R5 hydraulic hose is defined by a range that varies with its inner diameter (ID), a key characteristic tailored to its design for medium and low pressure hydraulic systems. Specifically, this steel wire reinforced hydraulic hose with a braided fiber cover offers pressure ratings spanning from 24 bar to 210 bar, with the exact value depending on the hose size.

At the larger end of the spectrum, a SAE 100 R5 hose with an inner diameter of 1-13/16 inches (approximately 46.03mm) is rated for 24 bar (348 psi), making it suitable for low-pressure applications where moderate fluid flow is prioritized over extreme pressure resistance. Conversely, the smallest size—3/16 inches (4.76mm) in ID—boasts a higher rating of 210 bar (3,046 psi), positioning it for medium-pressure tasks that demand greater strength without sacrificing flexibility.

This variability in pressure ratings is engineered to align with the hose’s structural composition: the steel wire reinforcement provides core strength to handle pressure, while the braided fiber cover enhances durability against abrasion and environmental wear. Such design nuances make SAE 100 R5 hose a versatile choice across industries, from agricultural machinery lubrication lines to industrial equipment where medium to low pressure hydraulic fluids (like mineral oils or water-glycol mixtures) are transferred.

For users seeking reliability, it’s critical to match the hose’s ID to the system’s pressure requirements—ensuring both safety and performance. Whether for small-diameter, higher-pressure applications or larger-diameter, lower-pressure needs, SAE 100 R5 hose delivers consistent performance within its specified range.Download as PDF