In industries ranging from construction to chemical processing, industrial hose plays a crucial role in ensuring safe and efficient operations. These hoses transport liquids, gases, and other materials under various pressure and temperature conditions. Choosing the right industrial hose manufacturer and understanding the types of industrial hoses available can make a significant difference in performance and durability.

There are various types of industrial hoses, each designed for specific applications. Below are some of the most common types:

These hoses are used for general-purpose applications such as supplying air to pneumatic tools and conveying water in industrial settings. They are usually made of rubber or PVC for flexibility and durability.

Designed to handle a wide range of chemicals, these hoses are resistant to corrosion and abrasion. They are commonly used in chemical plants, pharmaceutical industries, and laboratories.

Used for transferring oil, gasoline, and other petroleum-based products, these hoses are reinforced with special materials to withstand high pressure and prevent leaks.

Made from FDA-approved materials, food-grade hoses are used in the food and beverage industry to transport liquids such as milk, juice, and beer. These hoses ensure hygiene and safety in food processing.

Built to withstand high temperatures, steam hoses are used in industries such as manufacturing and power generation for transferring steam and hot water.

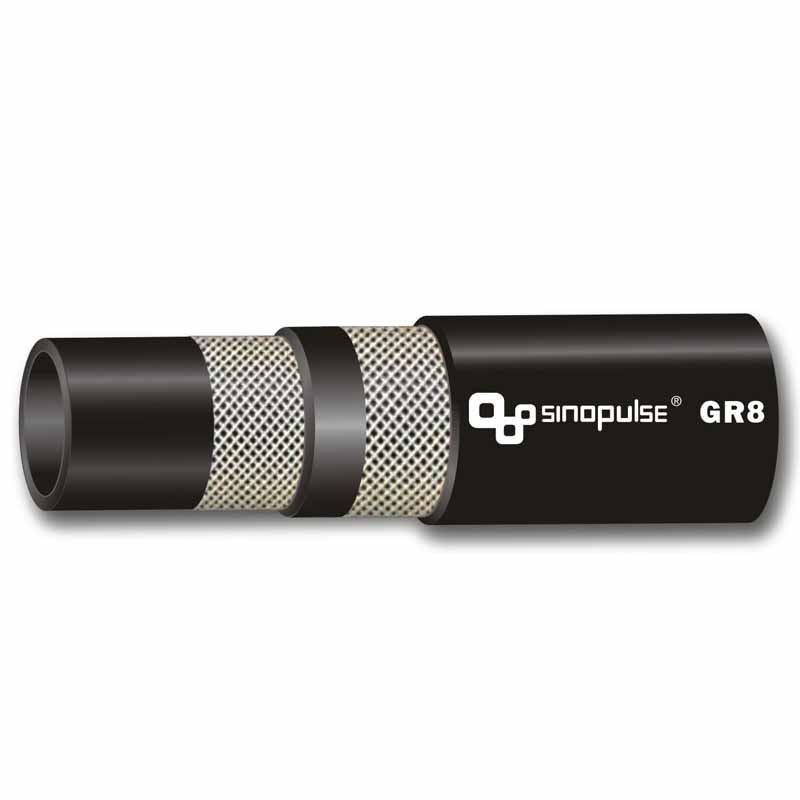

These hoses are used in hydraulic systems to transmit high-pressure fluid power. They are reinforced with braided or spiral wire for added strength and reliability.

Designed to move dry materials like cement, grains, and sand, these hoses are highly resistant to abrasion and wear.

Used for ventilation and air handling, ducting hoses are lightweight and flexible, often made of plastic or fabric materials.

Selecting a reliable

Look for manufacturers that adhere to international quality standards such as ISO 9001, ensuring that their hoses meet safety and performance requirements.

A good manufacturer offers hoses made from high-quality materials such as reinforced rubber, thermoplastics, or stainless steel, depending on the application.

Industrial applications often require custom solutions. Choose a manufacturer that provides tailored hose solutions, including length, diameter, and reinforcement layers.

Manufacturers with years of experience understand industry-specific challenges and can recommend the best hose for your needs.

Reliable manufacturers offer excellent customer support and warranties, ensuring long-term performance and assistance in case of issues.

Industrial hoses are used to transport liquids, gases, and materials in industries such as manufacturing, agriculture, and construction.

Consider factors such as the material being transported, pressure requirements, temperature conditions, and hose flexibility.

The lifespan depends on the material, usage conditions, and maintenance. Regular inspection and proper storage can extend the life of the hose.

Yes, many industrial hose manufacturers offer customization options, including size, reinforcement type, and material composition.

Always inspect hoses for wear and tear, ensure proper connections, and follow the manufacturer’s guidelines for pressure and temperature limits.

By understanding the types of industrial hoses and selecting the right industrial hose manufacturer, businesses can enhance efficiency, safety, and longevity in their operations.

Product Application