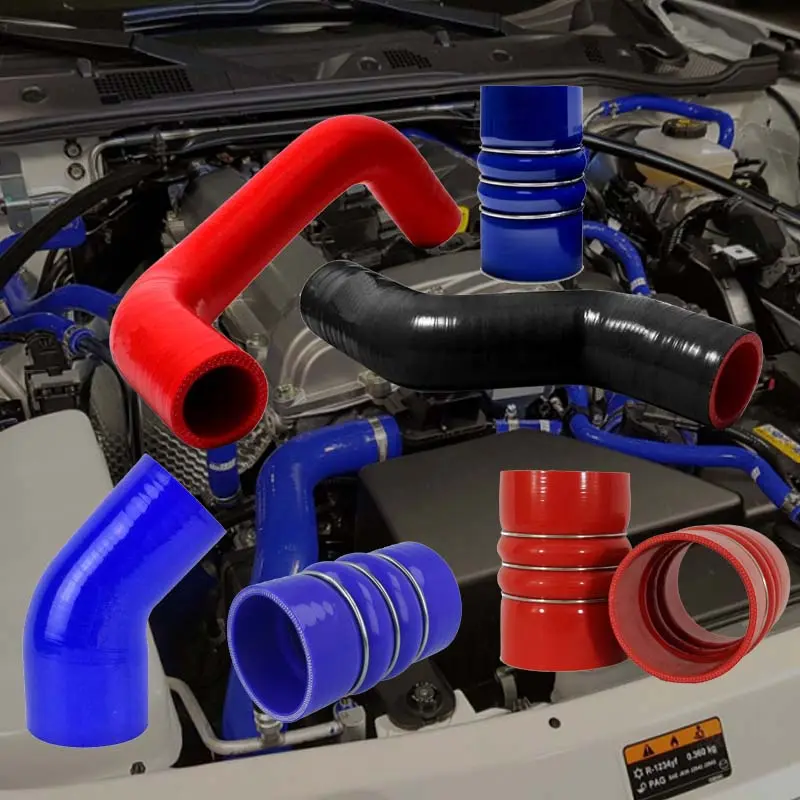

Modern vehicles rely on specialized components to ensure optimal performance, safety, and longevity. Among these components, custom automotive hoses play a critical role in fluid transfer, pressure management, and system efficiency. These hoses are designed to meet specific requirements, ensuring compatibility with different automotive applications. This guide explores the key types, materials, and applications of custom automotive hoses, focusing on their importance in vehicle maintenance and performance.

Automotive systems require various hoses to handle fluids under different conditions. One of the most common types is the fuel oil hose, which is used in fuel systems. These hoses are built to resist degradation from petroleum-based fluids, ensuring long-term durability. Another essential variant is the

For heavy-duty applications, an abrasion resistant hose is often necessary. This type is reinforced to withstand friction and external wear, making it suitable for undercarriage use or industrial vehicles. Meanwhile, the

The effectiveness of custom automotive hoses depends on their material composition. Most hoses are made from synthetic rubber, which offers flexibility and resistance to chemicals and heat. For instance, the

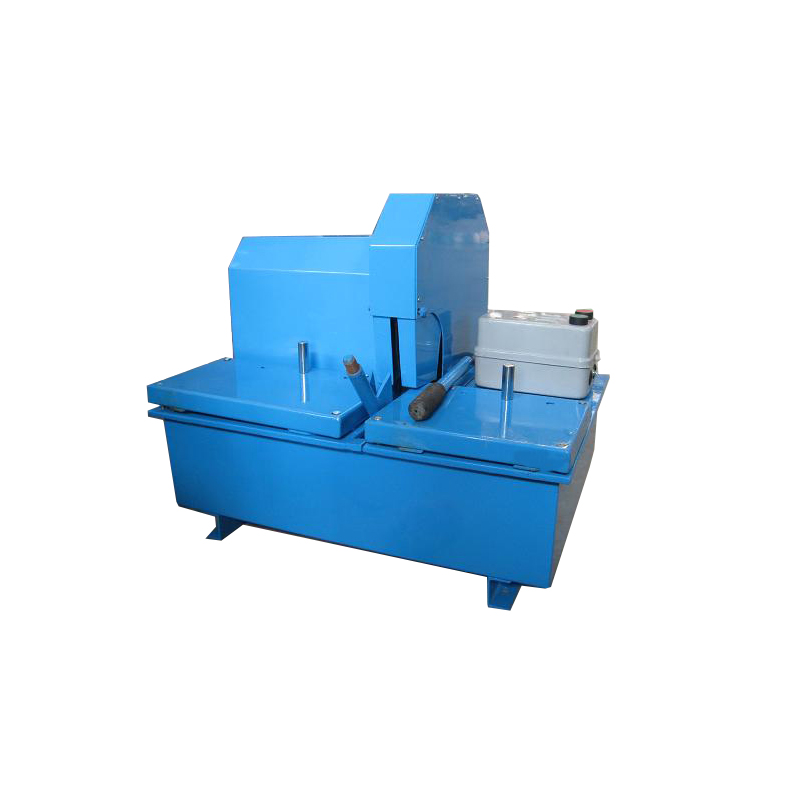

Reinforcement layers are another critical factor in hose durability. Many hoses feature braided or spiral-wound textile or steel reinforcements to handle high pressure. For example, a 300psi hose often includes multiple reinforcement layers to maintain structural integrity under stress. Additionally, some hoses incorporate specialized coatings to enhance abrasion resistance, particularly in environments where external wear is a concern.

The proper selection of custom automotive hoses requires careful consideration of fluid compatibility, pressure requirements, and environmental conditions. For petroleum-based fluids like fuel or oil, an

Pressure ratings represent another critical factor in hose selection. While standard cooling systems may use low-pressure hoses, fuel injection and power steering systems demand reinforced constructions. For high-pressure applications like cleaning systems, a

Environmental conditions significantly impact hose performance and longevity. Vehicles operating in harsh environments benefit from abrasion resistant hoses with protective outer covers to withstand road debris and chassis contact. Consider temperature extremes, UV exposure, and potential chemical contact when selecting materials. Some applications may require specialized compounds that maintain flexibility in extreme cold or resist degradation in high-heat environments.

Proper sizing and connection compatibility complete the selection process. Ensure the inner diameter supports adequate flow rates while the wall thickness meets pressure requirements. Match fitting types (JIC, NPT, or flange) to existing system components, and consider custom lengths to allow proper routing without excessive bending. Following these guidelines helps ensure optimal performance and extended service life for your custom automotive hoses in any application.

Custom automotive hoses play a vital role in maintaining vehicle performance by ensuring efficient fluid transfer across critical systems. From automotive fuel hoses to automotive air conditioning hoses in cooling applications, each type is engineered for specific conditions. Proper material selection, such as petroleum-resistant rubber for fuel lines or reinforced construction for high-pressure uses, directly impacts durability and safety.

Choosing the right hose requires careful consideration of fluid type, pressure ratings, and environmental factors. Regular inspections help detect wear in abrasion resistant hoses or leaks in rubber pressure washer hoses, preventing costly failures. By selecting quality custom automotive hoses and maintaining them properly, vehicle owners can optimize system reliability and extend service life across all automotive applications.

Product Application