In any hydraulic system, pressure is the heart that drives power and performance. Selecting the right hose pressure rating is critical not only for efficiency but also for safety and system longevity. Every hydraulic hose must handle specific levels of pressure that match the system’s requirements. Too low, and it risks bursting; too high, and it becomes inefficient and costly.

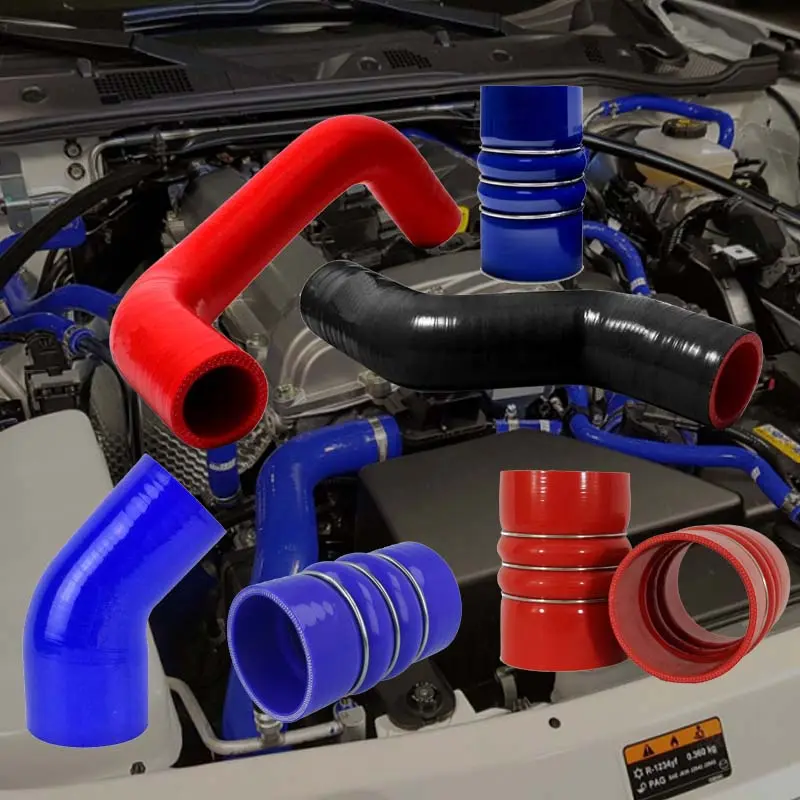

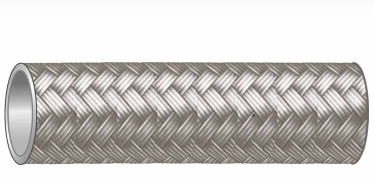

Hydraulic hoses are typically made from a combination of synthetic rubber, thermoplastics, and metal reinforcements, each contributing to the hose’s overall performance. The inner tube, often made of synthetic rubber or thermoplastic, must be compatible with the hydraulic fluid and resistant to degradation. The reinforcement layer, usually composed of braided or spiral-wound steel wire or textile fibers, provides the strength to withstand high pressures. The outer cover, made from abrasion-resistant materials like rubber or thermoplastic, protects the hose from environmental damage, including UV rays, chemicals, and physical wear.

The key to choosing the right hydraulic hose pressure lies in understanding WP (Working Pressure), BP (Burst Pressure), and the safety factor between them. WP is the continuous operating pressure a hose can safely withstand, while BP is the maximum pressure it can handle before failure. For most industrial hoses, a safety factor of 4:1 is used — meaning the burst pressure is four times the working pressure.

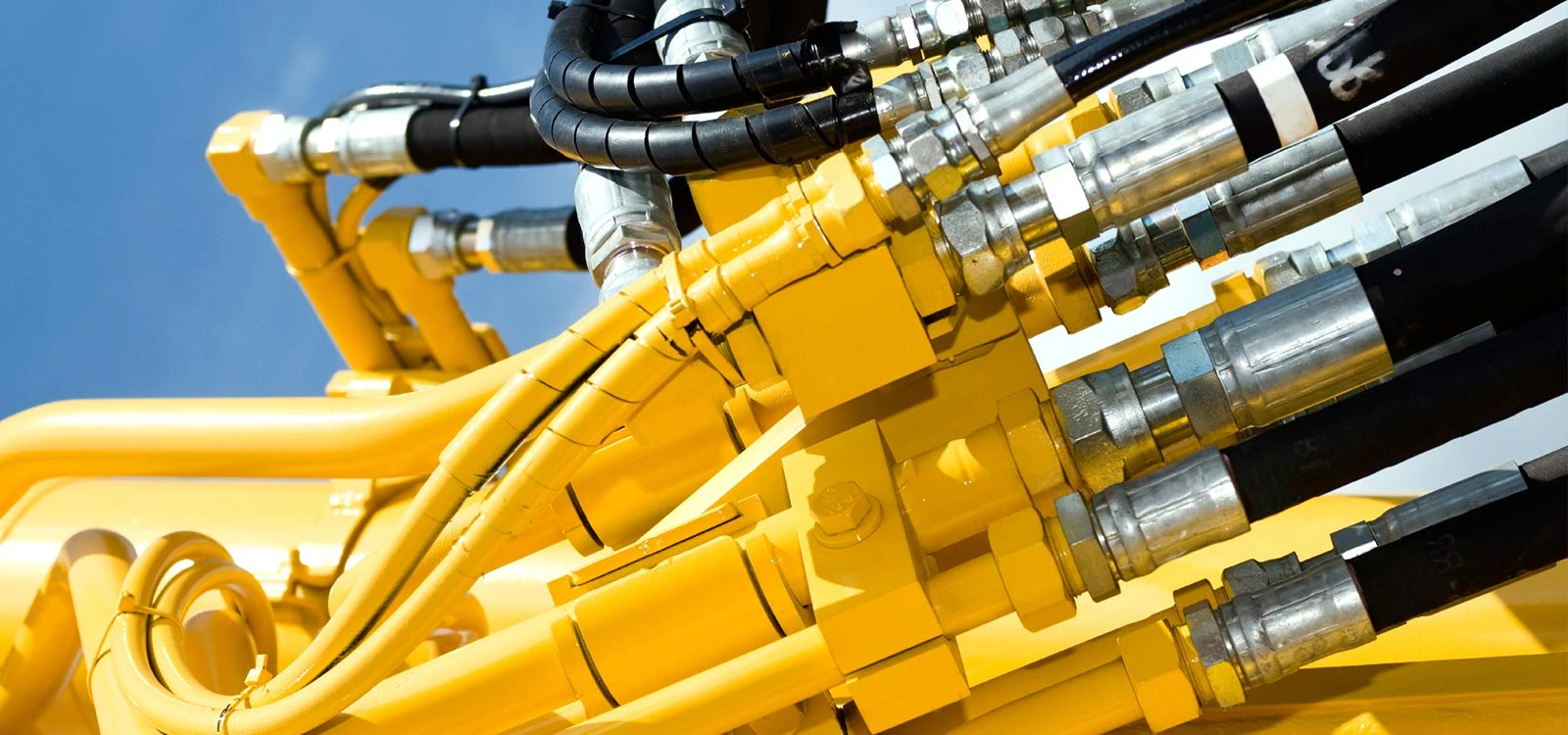

When working with medium- to high-pressure systems, the hydraulic hose is one of the most commonly used sizes. It offers a balance between flexibility and power transmission, suitable for heavy-duty applications such as excavators, tractors, or hydraulic presses. The diameter of the hose directly affects flow rate — larger diameters allow more fluid to pass through, reducing pressure loss over distance.

Choosing a hose requires understanding the system’s pressure rating, the type of fluid being used, and environmental factors such as temperature and abrasion. Always ensure that the WP (working pressure) of the hose exceeds the system’s maximum operating pressure. It is also essential to match the hose with the correct fitting type and assembly method to prevent leakage and ensure long-term reliability.

We can provide a wide range of types of hydraulic hoses, each coming in various sizes to meet different needs. Our various types of hose meet or exceed general standards such as SAE, DIN, and ISO. They are especially suitable for the manufacture and maintenance of construction machinery, agricultural equipment, and mining machines.

The 1/2 inch hydraulic hose is an excellent choice for medium-pressure hydraulic circuits. It’s often used in applications where compact routing and high flexibility are required — for instance, in industrial equipment or small construction vehicles. Despite its smaller diameter, a high-quality 1/2-inch hose can withstand significant pressures when reinforced with braided or spiral-wound steel wire.

This size allows the user to maintain high flow rates with less resistance, ensuring optimal efficiency. When selecting a 1/2-inch hydraulic hose, users should pay attention to the pressure rating (PSI), bend radius, and hose compatibility with hydraulic fluids. Improper selection can lead to overheating, bursting, or inefficient system performance.

In many hydraulic designs, engineers must also consider pressure spikes — short, sudden increases in system pressure. These spikes can exceed the WP, causing fatigue or even failure. Therefore, choosing a hose with an appropriate safety margin ensures system reliability.

The

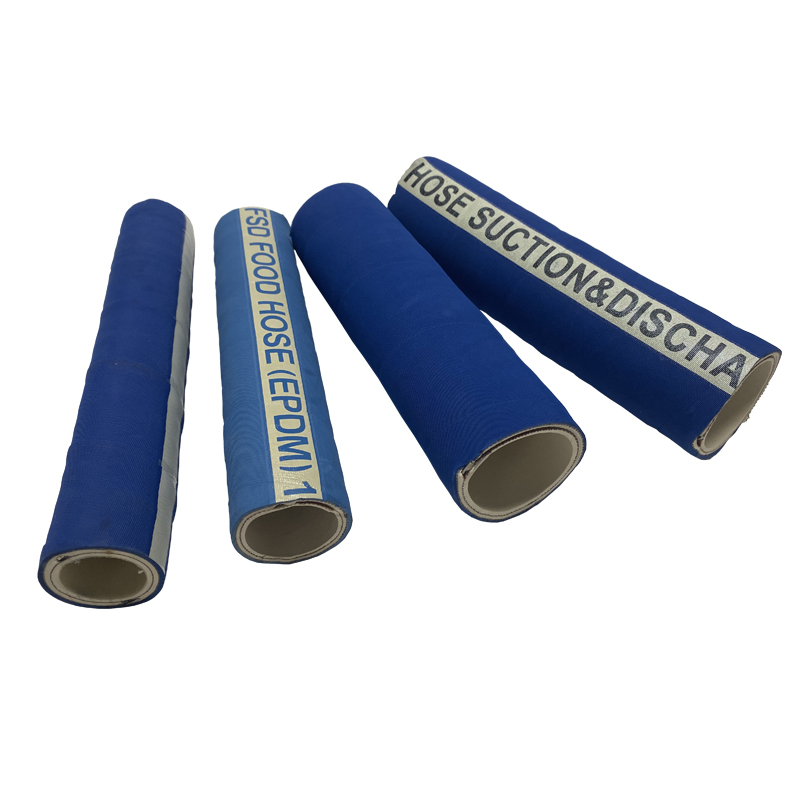

Because suction hoses handle lower pressure levels but must resist vacuum effects, flexibility and internal strength are crucial. They must also be highly resistant to hydraulic oil and temperature changes. Common applications include hydraulic tanks, return lines, and low-pressure fluid transfer.

When selecting a hydraulic suction hose, users should check the vacuum rating, temperature range, and bend radius. An inadequate hose may collapse, starving the pump of oil and leading to cavitation — a damaging condition that can destroy pump components. Using properly rated suction hoses improves pump efficiency, reduces noise, and extends equipment lifespan.

No matter how high-quality a hose is, wear and tear are inevitable. Hydraulic hose repair is therefore an essential part of maintaining system safety and performance. Early identification of leaks, cracks, or bulges can prevent catastrophic failures. When a hose fails under pressure, it can release fluid at high velocity, posing serious safety risks.

Routine inspection should include checking for abrasion on the outer cover, corrosion on metal fittings, and leakage at connections. Hoses exposed to extreme environments — such as heat, chemicals, or UV radiation — may degrade faster. Always replace damaged hoses immediately, and never attempt to patch them with temporary materials in critical systems.

Our hydraulic hose repair solutions ensure reliable performance by using original fittings and following manufacturer torque and assembly guidelines. Proper maintenance minimizes downtime and protects the entire hydraulic circuit from contamination, pressure loss, and damage to sensitive components.

Every hydraulic hose has two essential ratings: WP (Working Pressure) and BP (Burst Pressure). WP represents the continuous pressure the hose can safely handle during operation. BP, on the other hand, is the pressure at which the hose will fail under test conditions. The relationship between these two values defines the safety factor, which is typically 4:1 in most industrial hoses.

For example, a hose with a WP of 3000 PSI should have a BP of 12,000 PSI. This ratio ensures a buffer for unexpected spikes in system pressure. Some extreme applications, such as aerospace or deep-sea hydraulics, may use higher safety factors (up to 6:1 or 8:1) for added protection.

Users must always design systems based on WP, not BP. Running a hose near or above its WP for extended periods significantly reduces its lifespan and can lead to sudden failure. Regular inspection and pressure testing can ensure hoses remain within safe operating limits.

To determine the right pressure rating, first identify the maximum operating pressure of your system. Add a margin of 25–50% to account for pressure spikes or variations. Then, select a hose whose WP meets or exceeds this value. It is also crucial to consider environmental conditions — high temperatures, vibration, and fluid type can all affect hose performance.

For complex systems, engineers often use the “STAMPED” method: Size, Temperature, Application, Material, Pressure, Ends, and Delivery. This ensures every factor is considered before installation. Choosing the right hydraulic hose pressure guarantees not only performance but also operator safety and cost savings over time.

WP stands for “Working Pressure,” which refers to the maximum continuous pressure a hydraulic hose can safely handle during operation.

The safety factor is the ratio between burst pressure (BP) and working pressure (WP), usually 4:1, providing a safety margin for unexpected pressure spikes.

It depends on usage and environment, but most hydraulic hoses should be replaced every 3–5 years or immediately if damage, leaks, or swelling are detected.

Using a hose below the system’s required pressure can lead to bursting, leaks, or complete failure, causing equipment damage or safety hazards.

Yes, hydraulic hose repair is possible using the correct fittings and crimping equipment, but only if the hose body is structurally intact. Severely damaged hoses should always be replaced.

Product Application