- Description

- Product Tags

-

Key Features:

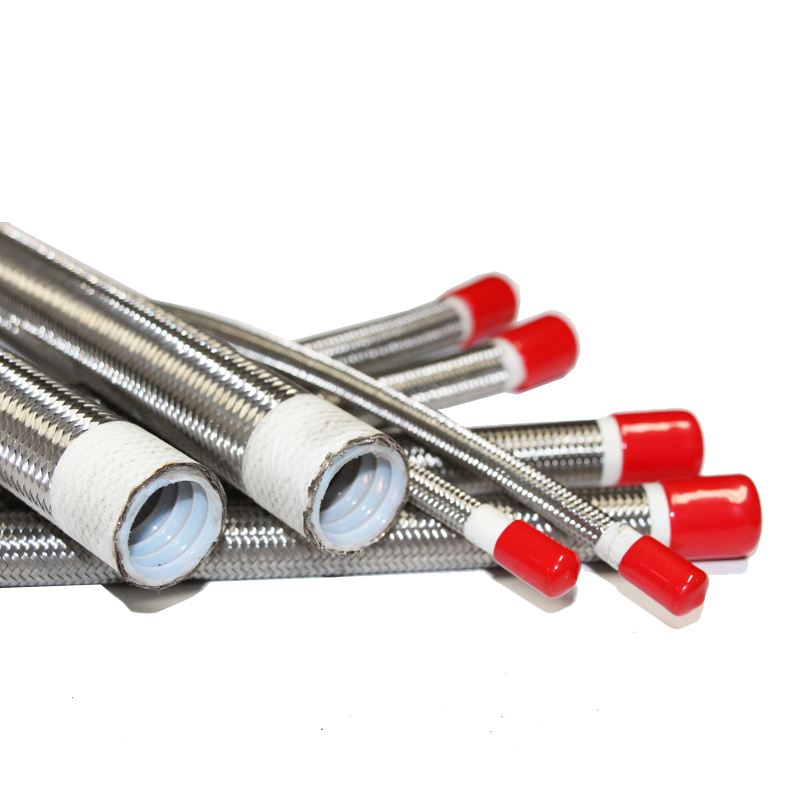

Hydraulic hose R14

EN/DIN and New SAE rated working pressure

Flame resistant property of the cover compoud

MSHA and ISO certificate

Smooth covery FRAS approved

OEM brand hose layline

Part No.

I.D.

O.D.

W.P

B.P

B.R

W.T

Dash

Inch

mm

mm

MPa

PSI

MPa

PSI

mm

mm

R14-02

1/8″

3.5

6.6

32.6

4727

97.8

14181

51

1.00

R14-03

3/16″

4.8

8.0

24.7

3582

74.1

10745

75

0.85

R14-04

1/4″

6.3

9.2

21.4

3103

64.2

9309

81

0.85

R14-05

5/16″

7.9

11.0

19.1

2770

57.3

8309

92

0.85

R14-06

3/8″

9.7

12.8

18.8

2726

56.4

8178

131

0.85

R14-08

1/2″

12.7

15.9

10.8

1566

32.4

4698

182

1.00

R14-10

5/8″

15.8

19.2

12.9

1871

38.7

5612

211

1.00

R14-12

3/4″

19.0

22.7

7.9

1146

23.7

3437

338

1.20

R14-14

7/8″

22.3

26.0

6.1

885

18.3

2654

421

1.20

R14-16

1″

25.4

29.3

4.8

696

14.4

2088

539

1.50

Application:

For carrying chemical and petroleum based hydraulic fluids.

SAE 100 R14 hydraulic hose is suitable for delivering petroleum or water-based hydraulic fluids in the working temperature of -54 °C to +204 °C. This kind of hose can be divided into two kinds according to the structure and material: type A and type B.

Type A is composed of tube and reinforcement. The tube is made from polytetrafluoroethylene (PTFE) and the reinforcement is made from one layer of 304 stainless steel.

Type B is almost similar to type A in structure, but it has an inner surface which is electrically conductive. And the inner surface is used to prevent the electrostatic charge.

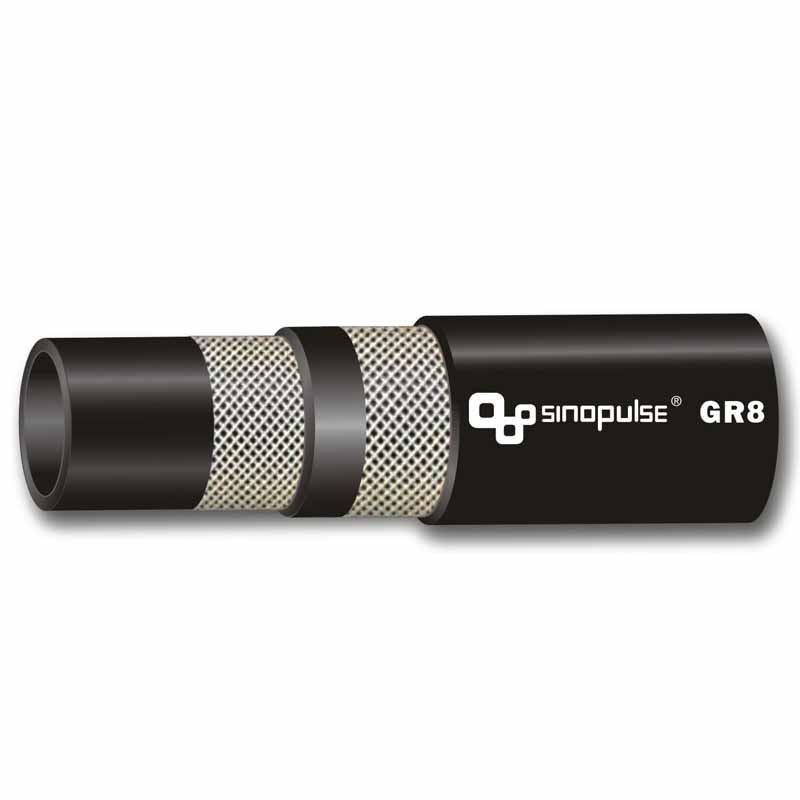

Sinopulse is a market-leading hydraulic hose manufacturer.

We offer hydraulic hoses that can deliver high performance and stand the hardest working environments. Our hoses are designed to perform in both high and low and pressures and are suitable for a variety of applications.Each of our hydraulic hose is in compliance with stringent industry standards such as SAE 100 and DIN.we also have iso and MSHA certificate.

Our reinforced hoses can fit a wide variety of adapters and fittings.

Our hydraulic hose is designed for use with petroleum- and water-based hydraulic fluids. It can handle gasoline, diesel fuels, mineral oils, glycol, lubricating oils and more.

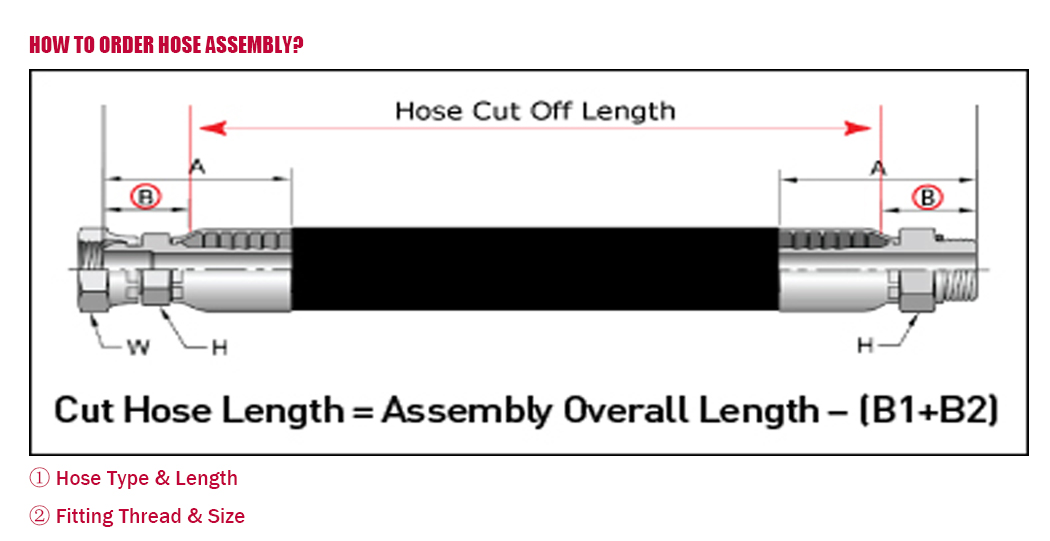

Hydraulic hoses handle high pressures in a wide range of fluid-power applications, from agriculture and manufacturing to all variety of heavy equipment operations.We can also make hydraulic assembly for customers.the finished assemblies are lengths of hydraulic hose with crimp fittings pre-attached. Customize the type of hose, length,and fitting to create the perfect assembly for your project.

We have a large hydraulic hose range, which can satisfy your different applications.

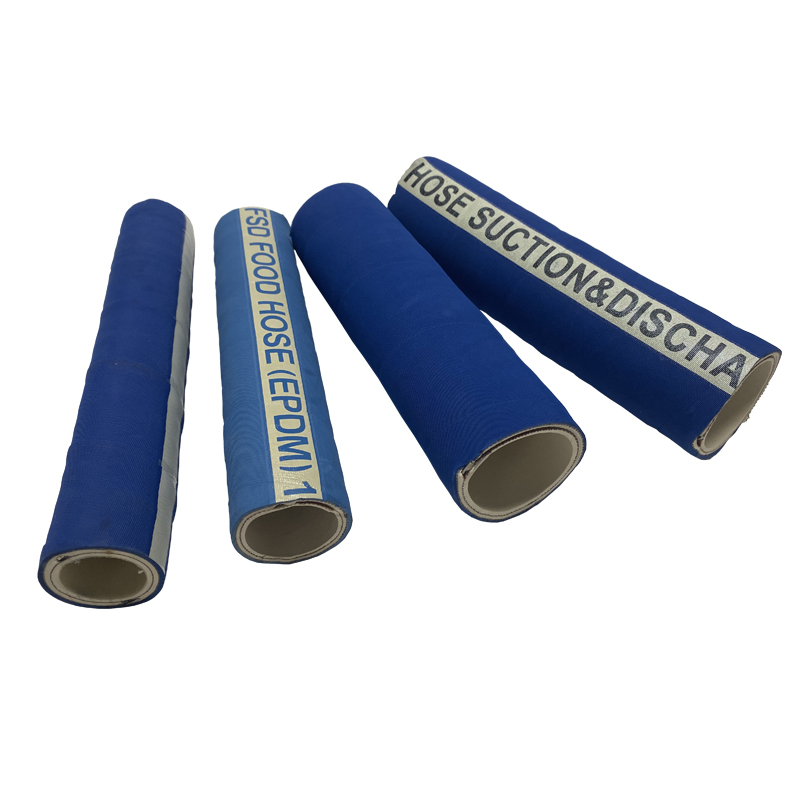

SAE100 R1AT/EN 853 1SN (ONE STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R2AT/EN853 2SN (TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

DIN 20023/EN 856 4SP (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

DIN 20023/EN 856 4SH (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R12 (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R13 (FOUR OR SIX STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R15 (SIX STEEL WIRE SPIRAL HYDRAULIC HOSE)

EN 857 1SC (ONE STEEL WIRE BRAIDED HYDRAULIC HOSE)

EN857 2SC (TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R16 (ONE OR TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R17 (ONE OR TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R3 / EN 854 2TE (TWO FIBRE BRAIDED HYDRAULIC HOSE)

SAE100 R6 / EN 854 1TE (ONE FIBRE BRAIDED HYDRAULIC HOSE)

SAE100 R5 (FIBER BRAIDED COVER HYDRAULIC HOSE)

SAE100 R4 (HYDRAULIC OIL SUCTION HOSE)

SAE100 R14 (PTFE SS304 BRAIDED)

SAE100 R7 (ONE WIRE OR FIBRE BRAIDED THERMOPLASTIC HOSE)

SAE100 R8 (TWO WIRE OR FIBRE BRAIDED THERMOPLASTIC HOSE)

Download as PDF

Download as PDF

As a vanguard among PTFE hose manufacturers, SINOPULSE engineers SAE 100 R14 hoses with a meticulous blend of innovation and precision. These PTFE braided hoses, fortified with stainless steel reinforcement, represent the pinnacle of performance in extreme industrial conditions, serving critical applications in aerospace, chemical processing, semiconductor manufacturing, and beyond.

The inner tube of SINOPULSE SAE 100 R14 hoses is crafted from premium polytetrafluoroethylene (PTFE), a material celebrated for its exceptional chemical inertness and thermal resilience. PTFE’s molecular structure renders it impervious to degradation from concentrated acids, caustic alkalis, and aggressive petroleum-based fluids, ensuring seamless compatibility with a vast spectrum of media. This chemical resistance is particularly crucial in pharmaceutical and semiconductor industries, where contamination risks must be minimized. Additionally, PTFE’s non-stick surface reduces friction by up to 80% compared to traditional rubber hoses, optimizing fluid flow and preventing pressure drop even in high-viscosity applications. Its ability to maintain flexibility across a staggering -60°C to +260°C temperature range ensures consistent performance from cryogenic storage to high-heat industrial furnaces.

Overlaying the PTFE layer is a stainless steel braided reinforcement composed of 304-grade alloy, a cornerstone of the hose’s mechanical prowess. This braided structure distributes internal pressure evenly, enabling the hose to withstand working pressures up to 4727 PSI and burst pressures reaching 14181 PSI—a safety factor of nearly 3:1. In mining or oil extraction equipment, where hydraulic systems endure constant vibration and abrasive conditions, the stainless steel braid acts as a shield, protecting the PTFE core from external wear and tear. Moreover, the braid’s interwoven design allows for a minimum bend radius 25% smaller than conventional hoses, facilitating installation in tight spaces such as aircraft engine bays or robotic hydraulic arms.

Completing the hose’s tri-layer architecture is a heat-resistant polymer outer cover, engineered to combat environmental threats. This layer provides superior protection against UV radiation, ozone, and mechanical impacts, extending the hose’s service life by up to 30% in outdoor or high-movement applications. In chemical plants or marine installations, the outer cover’s resistance to weathering and corrosion ensures the hose maintains structural integrity over prolonged exposure to harsh elements.

Together, the PTFE inner tube, stainless steel braid, and protective outer cover of SINOPULSE PTFE stainless steel braided hoses form a resilient system that excels in transporting corrosive chemicals, high-purity fluids, and abrasive materials. Whether you require a standard PTFE hydraulic hose or a customized solution, SINOPULSE’s commitment to engineering excellence ensures reliable performance across the most demanding hydraulic systems.

As a leading PTFE hose manufacturer, SINOPULSE’s anti-static SAE 100 R14 (Type B) hoses redefine safety and reliability in high-risk environments. Engineered as PTFE braided hoses with stainless steel reinforcement, these specialized products are designed to prevent electrostatic discharge (ESD), making them indispensable for industries where sparks pose catastrophic risks.

Fuel Transfer Systems: In the aerospace and automotive sectors, transferring highly flammable fuels like jet fuel or gasoline generates static electricity. SINOPULSE’s Type B hoses mitigate this danger with a conductive PTFE inner layer that safely dissipates static charges. The stainless steel braid acts as a grounding path, ensuring any accumulated charge is immediately neutralized. This feature is crucial for aircraft refueling operations and fuel storage facilities, where even a tiny spark could trigger explosions.

Chemical Processing Plants: When handling volatile chemicals or solvents, anti-static protection is non-negotiable. SINOPULSE PTFE stainless steel braided hoses excel in these scenarios, combining chemical resistance with ESD prevention. The PTFE material resists degradation from aggressive substances, while the anti-static design safeguards against ignition sources. This dual functionality makes them ideal for transporting solvents in paint manufacturing or hazardous materials in petrochemical plants.

Pharmaceutical and Food Industries: In environments requiring strict safety and hygiene, static electricity can attract contaminants or interfere with precision equipment. SINOPULSE PTFE hydraulic hoses address these concerns by eliminating static buildup, ensuring product purity, and operational integrity. Whether used in pharmaceutical fluid transfer or food processing lines, the Type B hoses meet stringent industry standards, providing peace of mind for critical applications.

SINOPULSE’s anti-static SAE 100 R14 hoses offer a comprehensive solution for safety-sensitive industries. Contact us to explore how our engineered products can enhance the safety and efficiency of your operations.