In the high-stakes world of welding, the integrity of your

welding hose

system is non-negotiable for both operational efficiency and worker safety. As a leading

A

- Safe Gas Transmission: Ensuring oxygen and acetylene reach the torch without leakage or contamination.

- Operational Stability: Withstanding the thermal and mechanical stresses of welding environments to maintain consistent performance.

Both oxygen welding hose and acetylene hoses are integral to creating the high-temperature flame necessary for metal fusion, but their design and functionality differ profoundly.

Designed to carry oxygen—a powerful oxidizer—this hose must resist combustion and chemical degradation. Key characteristics:

- Medium: Pure oxygen (O₂) for supporting combustion.

- Safety Imperative: Constructed to prevent ignition sources, as oxygen accelerates burning.

Engineered for acetylene—a highly flammable hydrocarbon gas—this hose prioritizes resistance to fuel degradation. Key characteristics:

- Medium: Acetylene (C₂H₂) as the fuel source for the welding flame.

- Design Focus: Flexibility and chemical resistance to handle acetylene’s reactive nature.

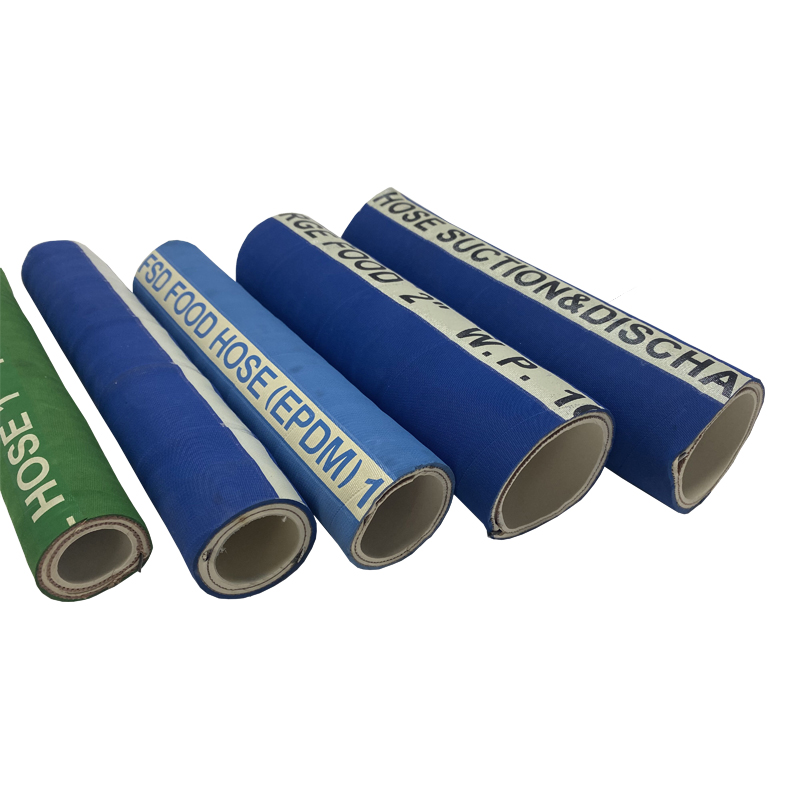

Industry standards dictate distinct color schemes for immediate recognition:

- Acetylene Hose : Traditionally red to signify a flammable gas, alerting users to potential fire hazards.

- Oxygen Hose : Commonly blue or green, indicating an oxidizing agent that amplifies combustion.

This color coding is not arbitrary; it’s a critical safety feature to prevent misconnection, which could lead to explosive mixtures.

- Acetylene Hose : Lower working pressure (typically 100–300 PSI), as acetylene becomes unstable at high pressures, risking decomposition.

- Oxygen Hose : Higher pressure tolerance (up to 1500PSI), designed to handle the compressed oxygen required for intense flames.

Mismatching pressure ratings can lead to hose rupture or gas leaks, underscoring the need for precise specification.

Oxygen Hose :

- Inner tube: Synthetic rubber (e.g., EPDM or NBR) with anti-oxidant properties.

- Reinforcement: Braided polyester or steel wire for pressure resistance.

- Critical Feature: Strict oil and grease resistance, as oxygen contact with hydrocarbons can cause spontaneous combustion.

Acetylene Hose :

- Inner tube: Specialized rubber compounds (often chloroprene) resistant to acetylene permeation.

- Reinforcement: Textile braiding for flexibility in tight spaces.

- Critical Feature: Resistance to solvents and fuel degradation, as acetylene can swell standard rubber.

- Verify the hose’s inner tube material matches the gas type. Oxygen hoses must be explicitly rated for oxidizing environments, while acetylene hoses need hydrocarbon resistance.

- Match the hose’s working pressure to your system’s requirements (e.g., 200 PSI for acetylene, 1500 PSI for oxygen).

- Consider temperature ranges; welding arcs can expose hoses to radiant heat, requiring heat-resistant outer covers.

- Look for hoses compliant with international norms (e.g., ISO 3821 for welding hoses or EN 559 for gas hoses).

- For food or medical adjacent applications, ensure additional certifications, though welding hoses typically focus on industrial safety standards.

- Bend radius: Acetylene hoses often require more flexibility for torch movement.

- Length: Optimize for your workspace to avoid excess slack that could cause tripping or kinking.

No . Swapping hoses creates a severe safety risk:

- Oxygen in an acetylene hose may ignite residual fuel.

- Acetylene in an oxygen hose can form an explosive mixture under pressure.

- Check printed markings: Hoses should be labeled “OXYGEN” or “ACETYLENE.”

- Inspect fittings: Oxygen hoses may have left-handed threads to prevent accidental connection to acetylene regulators.

Oxygen accelerates the oxidation of oils, generating heat that can ignite the hose. Even trace amounts of grease on an oxygen hose create a fire hazard, making degreasing mandatory during installation.

- Regularly inspect for cracks, swelling, or abrasion.

- Store hoses away from sunlight and chemicals when not in use.

- Replace hoses every 5–7 years or at the first sign of degradation, regardless of usage.

The distinction between oxygen and acetylene hoses is not just technical—it’s a matter of life and limb in welding operations. As a trusted

Whether outfitting a construction site, industrial workshop, or mobile welding rig, remember: color, pressure rating, and material composition are the three pillars of safe hose selection. Prioritize quality over cost, and always consult manufacturer guidelines to ensure your welding hose setup meets the highest safety standards.

Ready to enhance your welding safety? Explore our range of industrial-grade oxygen and acetylene hoses, engineered to deliver precision, durability, and peace of mind. Safety starts with the right hose—make the smart choice today.

–>