Modern industrial operations require fluid transfer solutions that combine durability, flexibility, and specialized performance characteristics. Our state-of-the-art thermoplastic hose products represent a significant advancement in hose technology, offering superior alternatives to traditional rubber hoses. Engineered for excellence across multiple industries, these high-performance hoses deliver exceptional results in the most challenging operating conditions.

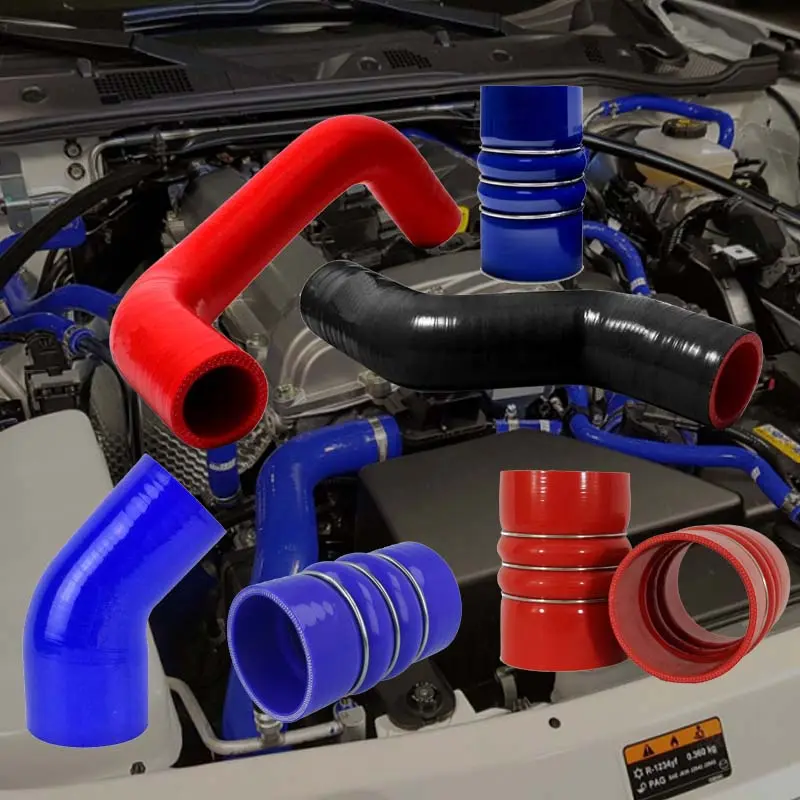

Thermoplastic hydraulic hoses, primarily made of thermoplastic materials such as nylon, polyester, and polyurethane, offer advantages such as light weight, excellent flexibility, and resistance to abrasion and chemicals. Common sizes include SAE 100 R7 and SAE 100 R8.

SAE 100 R7 hoses typically feature a nylon or polyester inner layer, a single-layer synthetic fiber braid reinforcement in the middle, and an outer layer of wear-resistant polyurethane. They are generally suitable for medium-pressure hydraulic systems. SAE 100 R8 hydraulic hoses, on the other hand, utilize a double-layer fiber braid for the reinforcement, resulting in a stronger overall structure and greater pressure resistance, allowing them to withstand higher operating pressures.

In environments where electrical hazards are present, our non conductive hydraulic hose provides essential protection against dangerous current transfer. These specialized hoses are constructed with advanced dielectric materials that completely isolate fluid systems from electrical pathways. The non conductive hydraulic hose is particularly crucial in utility applications, mining operations, and construction sites where accidental contact with power sources may occur. Beyond basic insulation properties, our hoses feature enhanced static dissipation technology to prevent dangerous charge buildup. The unique construction maintains all the performance characteristics of standard hydraulic hoses while adding this critical safety dimension. These hoses undergo rigorous dielectric testing to ensure consistent non-conductive properties throughout their service life, even after prolonged exposure to harsh environmental conditions.

Our

Our thermoplastic hydraulic hose series combines the advantages of advanced thermoplastics with the rigorous demands of hydraulic systems. These hoses offer superior resistance to petroleum-based fluids, synthetic lubricants, and other common hydraulic media that can degrade traditional rubber hoses. The thermoplastic hydraulic hose maintains excellent flexibility across a wide temperature range, performing reliably in both extreme cold and high-heat environments. The spiral reinforcement design provides exceptional burst resistance while allowing for tight bend radii without flow restriction. Unlike conventional hydraulic hoses, our thermoplastic versions are significantly lighter, reducing system weight and improving handling characteristics. These benefits make our thermoplastic hydraulic hose ideal for mobile equipment, industrial machinery, and aerospace applications where both performance and weight considerations are critical.

For applications demanding exceptional strength, our high pressure thermoplastic hose delivers uncompromising performance under extreme conditions. These robust hoses feature multi-layer construction with high-tensile reinforcement that withstands pressures exceeding conventional hose limitations. The high pressure thermoplastic hose maintains its integrity through thousands of pressure cycles, resisting the fatigue that causes standard hoses to fail. Specialized materials allow these hoses to achieve superior pressure ratings while remaining significantly lighter than comparable metal-reinforced alternatives. The smooth bore technology ensures efficient fluid transfer even at maximum pressure, minimizing turbulence and heat buildup. These hoses are particularly valued in oil and gas, heavy machinery, and industrial press applications where both extreme pressure capability and material compatibility are essential requirements. The abrasion-resistant exterior provides additional protection in harsh operating environments.

Our complete range of thermoplastic hose products addresses virtually every industrial fluid handling requirement. From the chemical resistance of our standard thermoplastic hose to the specialized capabilities of our high pressure thermoplastic hose, we offer solutions tailored to specific operational needs. These products share common advantages including longer service life, reduced maintenance requirements, and superior performance in challenging environments. The inherent material properties of thermoplastics allow for thinner wall constructions without sacrificing strength or pressure capacity, resulting in lighter, more manageable products. Our engineering team can recommend the perfect hose configuration based on your specific fluid type, temperature range, pressure requirements, and environmental conditions. With excellent resistance to kinking and crushing, these hoses maintain reliable performance even in space-constrained installations.

Our thermoplastic hydraulic hose maintains excellent performance across an exceptional temperature spectrum, suitable for both arctic conditions and high-heat industrial environments without compromising flexibility or strength.

The non conductive hydraulic hose incorporates multiple dielectric barriers and static-dissipative layers that prevent current transfer while safely grounding any static buildup that could create ignition hazards.

Our high pressure thermoplastic hose combines exceptional pressure rating with chemical resistance to drilling fluids and hydrocarbons, while remaining flexible in extreme weather conditions.

Yes, we offer food-grade thermoplastic hose pipe versions manufactured with FDA-approved materials that resist bacterial growth and won’t impart taste or odor to transferred products.

Properly selected thermoplastic hose typically lasts significantly longer than rubber equivalents due to superior resistance to environmental factors, abrasion, and chemical degradation.

Transform your fluid handling systems with the advanced performance of our thermoplastic hose technology. Contact our engineering team today to discover how these innovative solutions can improve reliability, safety, and efficiency in your operations. From specialized non conductive hydraulic hose requirements to extreme-pressure applications, we have the expertise and product range to meet your most challenging fluid transfer needs.

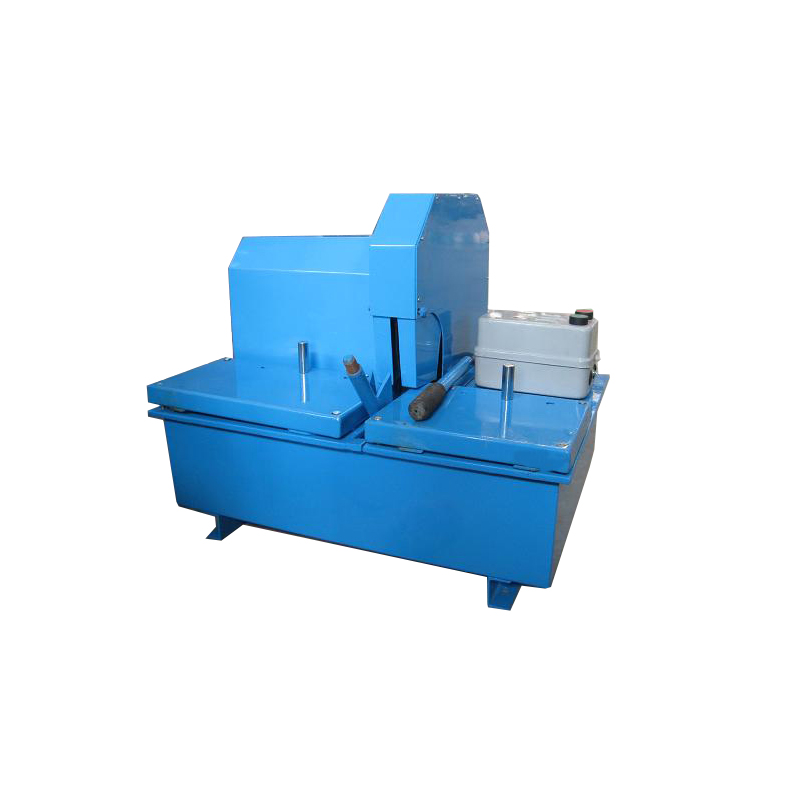

Product Application