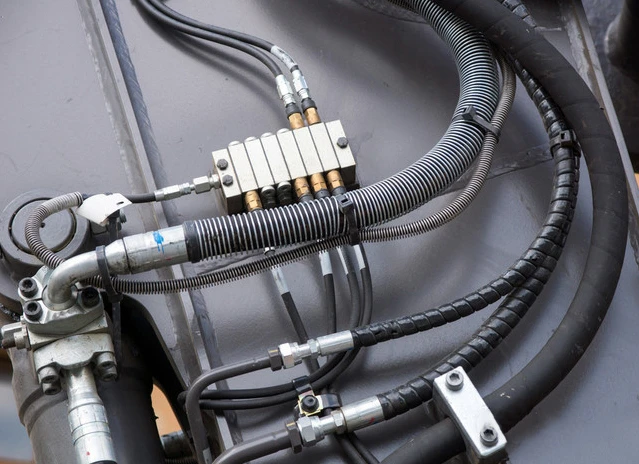

Flexible hydraulic hose, as an indispensable and important component of hydraulic systems, is widely used in various fields such as industry, engineering machinery, automobiles, and aviation. It is used to transport hydraulic oil or other fluids, and its performance and lifespan have a crucial impact on the stability and safety of the entire hydraulic system. However, regarding the lifespan of hydraulic return hose, many users often have certain misconceptions in practical applications, leading to unnecessary economic losses and safety hazards.

Among them, the material, working environment, usage pressure, medium type, bending radius, and maintenance of the hose will directly affect its service life. Generally speaking, the manufacturing materials for forklift hydraulic hoses mainly include synthetic rubber, polyurethane, polyethylene, and metal. The characteristics of these materials determine the oil resistance, wear resistance, and temperature resistance of the hose. For example,

At the same time, excessive work pressure can also shorten its lifespan, especially in frequently changing pressure environments, where fatigue damage to hydraulic pump hoses becomes more significant. Therefore, choosing the working pressure of the hose reasonably and avoiding overloading as much as possible can effectively extend its service life.

Some hydraulic oils contain additives that are corrosive to hose materials, and prolonged contact can cause hose hardening, cracking, and even eventual failure. Therefore, selecting suitable hydraulic media and following the manufacturer’s recommendations for regular inspection and replacement are equally important measures to extend the lifespan of flexible hydraulic hoses.

Regularly inspecting the appearance and interface of the hose, promptly identifying and resolving potential issues, can prevent minor faults from escalating into major problems. In addition, when laying hoses, attention should be paid to a reasonable bending radius to avoid twisting and stretching, in order to minimize the mechanical stress on the hoses.

In summary, the lifespan of flexible hydraulic hose does not have a fixed value and is influenced by various factors. Under good usage and maintenance conditions, high-quality flexible hydraulic hoses can typically exert their effects for thousands of hours or even longer. However, in order to ensure the safe and efficient operation of the hydraulic system, users should conduct regular inspections and maintenance to maximize the service life of flexible hydraulic hoses and ensure the normal operation of the system.

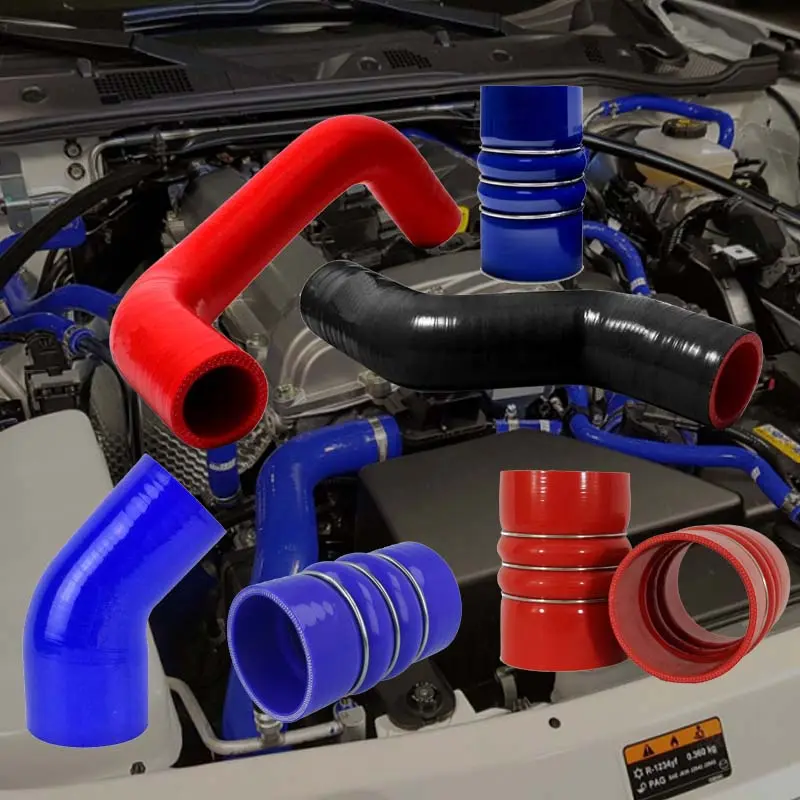

Product Application