Hydraulic hoses are flexible conduits designed to transmit pressurized fluid within a hydraulic system. These hoses typically consist of three layers: an inner tube that carries the fluid, a reinforcement layer that resists pressure, and an outer cover that protects against abrasion, weather, and chemicals. Hydraulic systems use incompressible fluids such as oil or synthetic fluids to generate high forces that operate machinery, lifts, or heavy construction equipment.

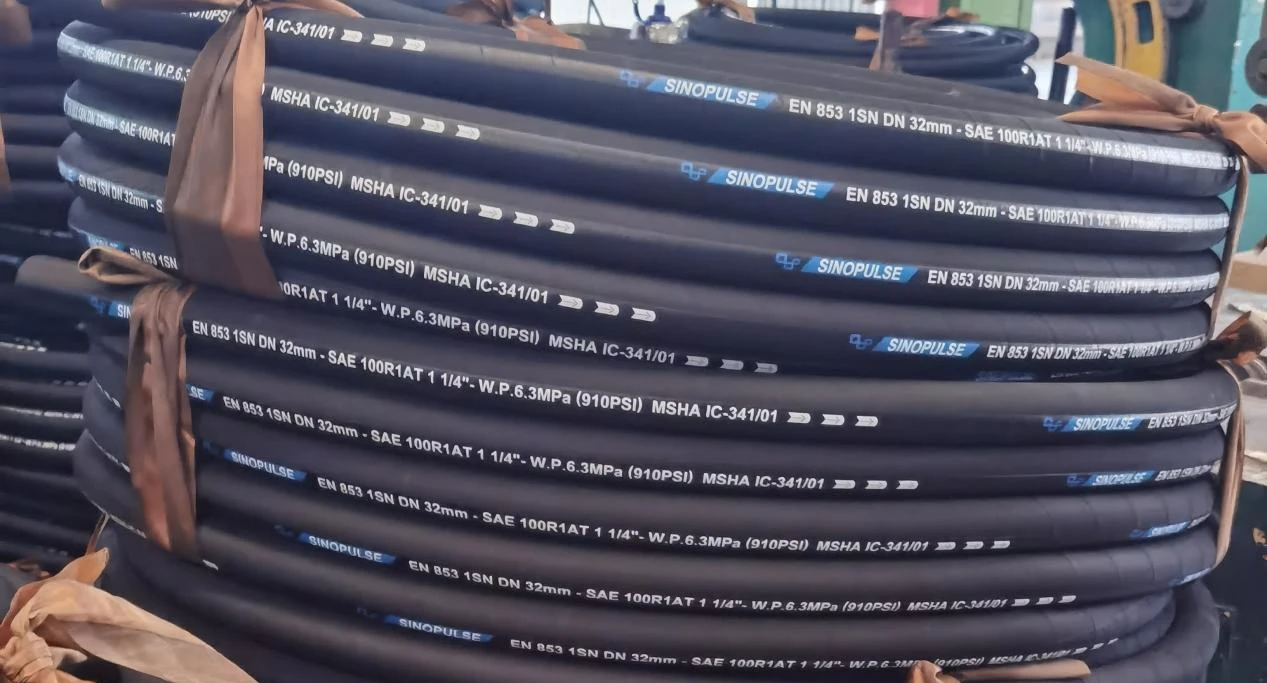

High pressure hose manufacturers design and produce hoses capable of handling extreme operating pressures, often exceeding thousands of PSI. These hoses are essential for applications such as excavators, agricultural tractors, hydraulic presses, and injection molding machines. Because hydraulic systems depend on high-pressure energy transfer, the hose’s construction must be extremely durable, with steel wire or spiral reinforcements to maintain structural integrity under load.

Hydraulic hoses are also required to comply with international standards such as SAE, ISO, and DIN. Each specification defines the hose’s pressure rating, temperature range, and compatibility with fluids. In these systems, even minor leakage or fitting failure can lead to performance loss or equipment damage, which is why manufacturers emphasize rigorous testing and quality control.

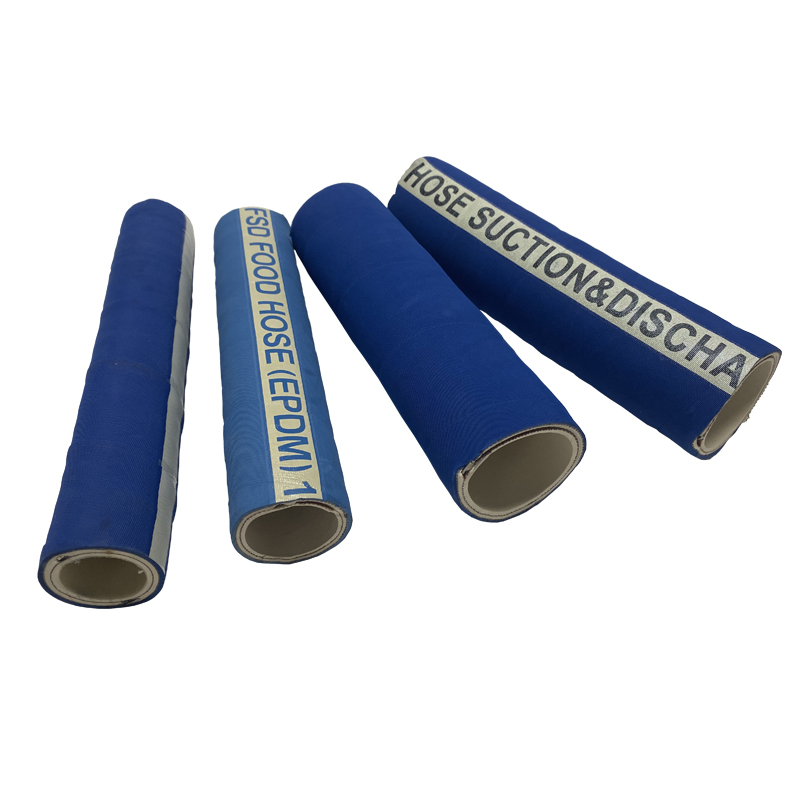

In contrast, pneumatic hoses carry compressed air or gases instead of hydraulic fluid. They are commonly found in lighter-duty applications such as air tools, automation systems, spray painting, or industrial robotics. Since air is compressible, pneumatic systems typically operate at much lower pressures (often under 300 PSI) compared to hydraulic systems.

While hydraulic hoses must resist oil and heat, pneumatic hoses prioritize flexibility, kink resistance, and resistance to water vapor or oil mist from compressors. Because of these differences, pneumatic hoses are more economical and easier to replace but are not designed for high-pressure environments.

Although they appear similar at first glance, hydraulic and pneumatic hoses serve very different purposes. Hydraulic hoses handle liquid power transmission , while pneumatic hoses manage air flow control . This fundamental difference leads to variations in design, materials, fittings, and performance.

From a hydraulic hose specifications perspective, hydraulic hoses have higher pressure ratings (up to 6000 PSI or more), while pneumatic hoses usually stay below 300 PSI. The construction of hydraulic hoses involves steel wire braids or spirals for reinforcement, whereas pneumatic hoses often rely on textile reinforcement or none at all.

Temperature tolerance is another major difference. Hydraulic hoses can withstand temperatures ranging from -40°C to +120°C, depending on the material and fluid type. Pneumatic hoses, being used with air, generally handle lower temperatures and pressures. Additionally, hydraulic systems are closed and fluid-based, meaning leaks can cause contamination and energy loss, while pneumatic systems vent air to the atmosphere and are less prone to fluid hazards.

In terms of safety and reliability, hydraulic hoses must meet strict burst pressure and impulse testing standards. Pneumatic hoses, while simpler, need to maintain flexibility to ensure smooth air delivery without cracks or leakage.

A common question in fluid power industries is whether hydraulic and pneumatic hoses can be used interchangeably. The short answer is no — each hose type is engineered for specific media, pressures, and applications.

Hydraulic hoses are built to handle non-compressible fluids under extreme pressures. Using them in a pneumatic system would be inefficient and unnecessarily heavy. Conversely, using pneumatic hoses in a hydraulic system is dangerous because they lack the structural reinforcement to withstand hydraulic pressure, leading to bursting or catastrophic failure.

That said, in some low-pressure or experimental systems, limited interchangeability might occur under strict engineering control, but it is never recommended for industrial or commercial machinery. Always refer to manufacturer data and technical documentation before substituting hose types.

Manufacturers provide detailed hydraulic hose catalogue listings that specify each hose’s pressure rating, temperature limits, material compatibility, and recommended applications. Consulting this catalogue is essential before selection to ensure the right product is used in the right environment. Proper adherence to catalogue data prevents failure, improves performance, and extends service life.

Hydraulic hose fittings play a crucial role in connecting hoses to other components in a hydraulic system, such as pumps, valves, or cylinders. Different types of hydraulic hoses have their own requirements when it comes to choosing the appropriate fittings.

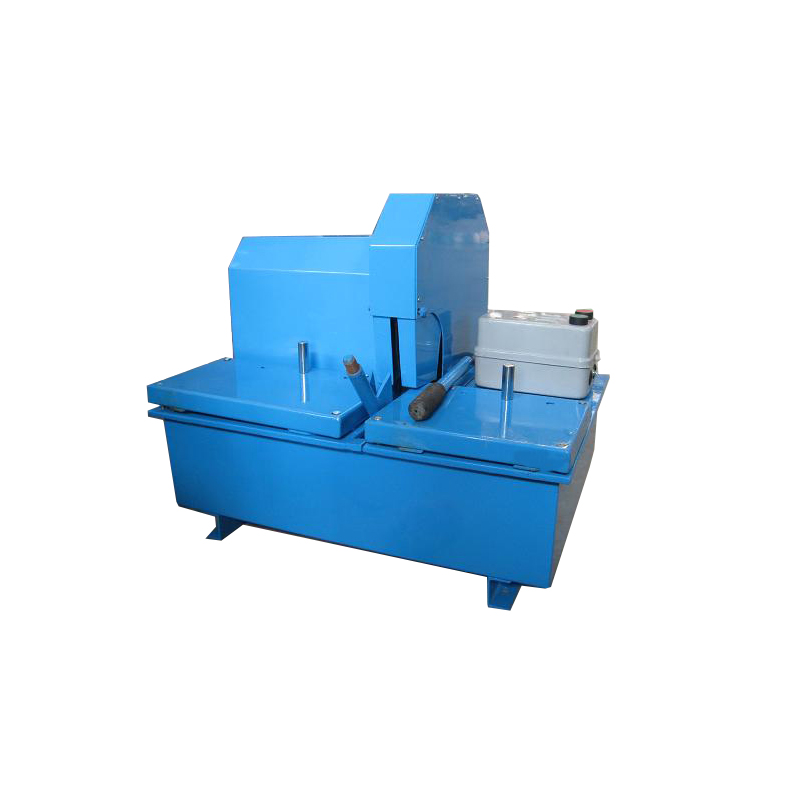

These fittings come in various types, including threaded, crimped, and quick-connect styles, each suited for specific applications. The choice of fitting depends on factors such as the system’s operating pressure, the type of fluid, and the compatibility with the hose material. For instance, industrial high pressure hoses , which are designed to withstand significant pressure, often pair well with crimped fittings that offer strong, reliable connections for high-pressure systems. Spiral hydraulic hoses, known for their durability and flexibility in certain applications, also need fittings that can complement their structural characteristics.

Threaded fittings are common and provide a secure connection, but they require careful tightening to prevent leaks. Crimped fittings, often permanently attached, offer strong, reliable connections for high-pressure systems. Quick-connect fittings are ideal for applications requiring frequent assembly or disassembly, such as in mobile equipment. When selecting a fitting, consider the size and thread type to ensure a proper match with the hydraulic hose and system components. Custom made hydraulic hoses might have unique dimensions or material properties, making it even more essential to choose fittings that are specifically compatible.

Always follow the hydraulic hose specifications and manufacturer’s guidelines to avoid compatibility issues that could compromise system integrity or lead to leaks. By ensuring that fittings match the system’s requirements, operators can prevent downtime, maintain safety, and maximize hydraulic efficiency.

Hydraulic hoses transmit liquid under high pressure, while pneumatic hoses carry compressed air at much lower pressures.

No. Pneumatic hoses lack the internal reinforcement and chemical resistance required to handle hydraulic oil under pressure.

Although possible in very low-pressure systems, it is inefficient and not recommended due to excess weight and potential condensation issues.

Always refer to the hydraulic hose catalogue or manufacturer’s specifications to select hoses based on working pressure, temperature range, and media compatibility.

Fittings ensure secure connections between hoses and system components. The right fitting type prevents leaks, ensures safety, and maintains hydraulic efficiency.

–>